Adding primings was very common amongst British breweries, and I’m sure it must still go on. It’s fascinating which pieces of equipment were insisted upon.

“Priming

Before an attempt is made to dissolve priming or syrups of any kind, it is as well for a brewer to make himself acquainted with the conditions required by the Excise. The necessary notice for dissolving and the quantity to be used must be entered in the Excise book. Not less than three vessels must be brought into use when the priming solution is prepared, and they should be a dissolving vessel, a cooling vessel (refrigerator), and a collecting vessel. All of them are required to bear the usual distinguishing marks, and must also have been duly entered in the brewing inventory. The collecting vessels must, in addition, have been gauged in order that the contents can be checked for duty charge. It must be noted that priming, like brewing sugar, may only be stored in vessels and departments specially entered in the brewing inventory for this purpose. On no account will the Excise allow the addition of priming to beer when in the cellars of licensed premises, although dispensations can be obtained in regard to bottling stores and other depots in responsible control.”

"Brewing Theory and Practice" by E. J. Jeffery, 1956, page 245.

All the bits of kit demanded are basically concerned with tax collection. The excise wanted to be able to see what was going on with the sugar. Because tax was charged of the gravity of the wort before fermentation. And the same was true of primings, tax was payable on their gravity. And the excise was particularly against any type of sugar being in a pub cellar. Too easy for a dodgy publican to water his beer and cover it up by adding sugar.

These are the relevant bits of kit in an illustration from the book:

"Priming soon develops a spontaneous fermentation, especially during hot weather, and it is essential to use it when fresh and new. It should be made frequently in small quantities, rather than less often in larger amounts. Priming is a very penetrating solution, and on that account, wood is an unsuitable material from which to make a collecting or storage vessel. Everything must be kept particularly clean and sterile.”

"Brewing Theory and Practice" by E. J. Jeffery, 1956, page 245.

That’s not the sort of spontaneous fermentation Lambic undergoes. He just means that it starts fermenting without the addition of extra yeast.

Here’s the point of priming:

“The real objects for using priming are twofold. First to promote the development of cask condition, and secondly, to impart an additional fullness to the palate of the beer. In order to achieve these objects, many primings have been introduced by various firms under different names, some of which differ in only a small degree. We are not going to mention any by name, but leave it to the brewer to choose and use one which he considers most suitable for his class of beer. The fashionable palate of the district where the beer has to be sold should of course be borne in mind. No difficulty should be experienced in obtaining from the makers of any priming a full analysis, showing particularly the extract given, the proportion of fermentable and unfermentable sugars, the amount of ash and mineral matters. It is important to have particulars of all these features.”

"Brewing Theory and Practice" by E. J. Jeffery, 1956, page 245.

The first purpose is pretty obvious. The alternative to priming would be to leave enough fermentable material in the beer to achieve cask condition. A much trickier feat than fermenting the beer all the way down then adding back in the required amount of fermentable material for cask conditioning.

Different primings were used for different types of beer:

“First consideration must be given to the flavour which the priming will impart. The brewer must also not lose sight of the class of beer for which the sugar is required. It is obvious that to use a priming consisting mostly of dextrins for a running beer intended for quick consumption is to defeat the object of the sugar. It would nevertheless add some palate fullness. On the other hand, little benefit would be derived from the use of a priming containing a low proportion of malto-dextrin with beers which are to be stored for ten days or a fortnight. The effects of such a priming would undoubtedly have worn off, especially if it was added at the time of racking. In some districts where beers are preferred to drink very sweet, priming made from sugar-candy gives the desired results. Unfortunately it is not a sweetness which lasts for any length of time, as this sugar ferments rapidly.”

"Brewing Theory and Practice" by E. J. Jeffery, 1956, pages 245 - 246.

It makes sense that you wouldn’t want to prime with anything too fermentable if you were going to have the beer sit around in the brewery for a couple of weeks.

Not just the type of primings but when they were added was important:

“It will therefore be gathered that the problem of selecting the most suitable priming is one which needs careful consideration. Equally important is the correct time at which the priming should be added. For running beers we prefer to add it at racking time, preferably in the racking back where it can be easily distributed. The risk of infection by handling small quantities while measuring out is also eliminated. For beers intended for comparatively short storage we prefer to add half the quantity at racking time, and the remainder just before the beer leaves the brewery. This procedure must never be adopted, however, if the beer is inclined to fret or be turbid, as the trouble would only be intensified. Indeed, it should be a strict rule that priming must never be added to beer under such conditions. These remarks should also apply to stock ales, because the primary yeast will probably have been exhausted, and will be unable to keep in check any secondary or wild yeast, which priming may revive. As a final recommendation with regard to priming, we advise daily microscopical examination of all priming to be used, and the rejection of any about the soundness of which there is the slightest doubt.”

"Brewing Theory and Practice" by E. J. Jeffery, 1956, page 246.

Again, all pretty logical stuff. I can certainly see the advantage of priming the beer in bulk rather than fiddling around adding adding a couple of pints to each barrel.

And here’s something about the priming rate:

“Priming solution is generally made to a gravity of 53 lb. (sp.gr. 1148) and added at the rate of 1 to 3 pints per barrel. Occasionally for sweet mild ales which are to be drunk quickly, up to 4 pints are used. (Calculations for the quantities of sugar and liquor required are given on p. 63.)”

"Brewing Theory and Practice" by E. J. Jeffery, 1956, page 246.

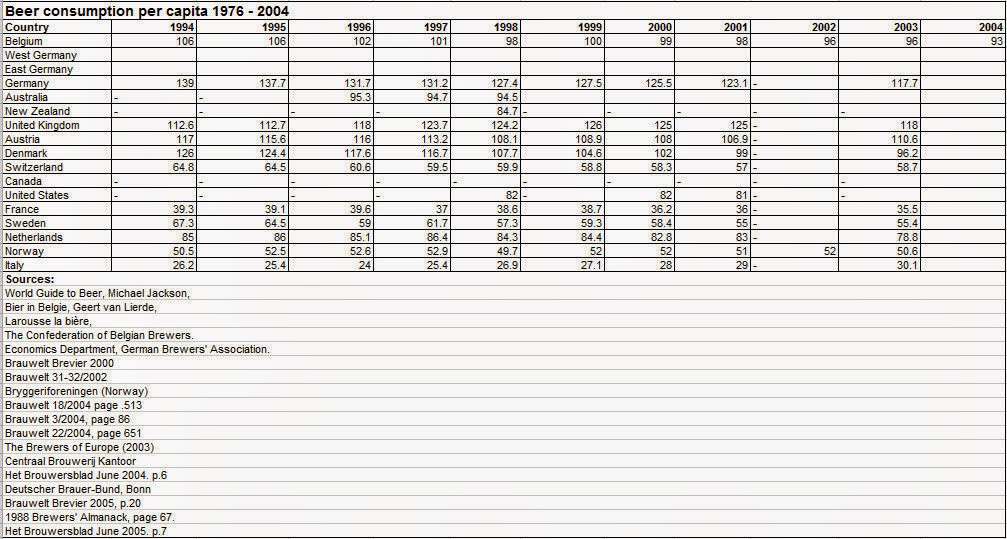

I can check this with Barclay Perkins records as they clearly state what primings were added. Here are some examples:

They were adding 1 to 4 quarts per barrel. Rather more than Jeffery suggests. You can see though that the gravities, at 1144º and 1150º were pretty much as stated in the book.

Interestingly, not all their beers were primed. The Milds and K Ales were. The Porters and Stouts weren’t. The Pale Ales weren’t, either, with the exception of the Export version of their PA.

Fining next.