Just like every other 18th-century source I've seen on malting, the author wasn't very keen on wood as a fuel. In particular because of the horrible smoky tang it gave to the finished beer.

Of the drying of malt.

There is a dispute among malsters, about the thickness the malt should lie upon the hair cloth for drying. Our ancestors spread it very thin, they rarely let it lie at more than three inches deep : our late improvers, as they call themselves, lay it fix inches or more; but this is a great error. About four inches is a proper thickness: in this manner a space of fifteen foot square will dry two quarters of malt. It is not to lie all the time quiet. It must be turned upon the hair cloth as upon the floor, more or less, according to the nature of the fire, and the time intended to be allowed. If the fire be gentle, and 'tis a pale malt, that is to have ten or twelve hours on the hair cloth, once in four hours is very well for the turning: if it be a kind that must dry quicker, once in two hours will be a proper method : observing to keep a clean bottom. When the malt is sufficiently dried, it must be thrown off from the kiln to the floor, and spread thin and wide. in an airy place, that it may cool. Then it is finished and fit for use.

There is not, in all the common arts of life, any that requires so nice a caution as the making of malt. The time mull be considered : three weeks is a moderate allowance, often it will take much longer. As different lengths of time are required for drying malt, there have been invented various ways of doing it. The iron-plate frame, and the tile frame, both full of small holes, are esteemed by many; others prefer the brass-wire and others the iron-wire frame ; and others the hair cloth: the husbandman is not to give his voice in favour of any one of these in general terms ; but to consider the use it is intended to answer : the nature of the malt to be dried is a material consideration, for that kind will do for one that will not for another; and when the most expeditious can be used, without hurt, there is something in the saving of fewel. Those which do with the least fewel are the iron-plate frame and the tile frame : they were invented for this purpose, and are a ready and cheap method. They dry the brown malts very well, but they will not answer for the pale.

There is not, in all the common arts of life, any that requires so nice a caution as the making of malt. The time mull be considered : three weeks is a moderate allowance, often it will take much longer. As different lengths of time are required for drying malt, there have been invented various ways of doing it. The iron-plate frame, and the tile frame, both full of small holes, are esteemed by many; others prefer the brass-wire and others the iron-wire frame ; and others the hair cloth: the husbandman is not to give his voice in favour of any one of these in general terms ; but to consider the use it is intended to answer : the nature of the malt to be dried is a material consideration, for that kind will do for one that will not for another; and when the most expeditious can be used, without hurt, there is something in the saving of fewel. Those which do with the least fewel are the iron-plate frame and the tile frame : they were invented for this purpose, and are a ready and cheap method. They dry the brown malts very well, but they will not answer for the pale.None of the methods heat the malt so violently as these, the corns often jump like parched pease, and crack: but they get -a fine brown. It is a cheap way ; but let the farmer fee he is not deceived in it, especially if he buy malt of this brown fort. The nature of it is to look dry, and it is not the worse for that; but those who fell it, frequently sprinkle water over it, and this makes it swell up vastly. 'Tis fairer to the eye, but this takes away a great deal of its sweetness.

People find the Brown malt dried this way apt to spoil in keeping : but they accuse the machine, when the malsters are in fault: all the damage is owing to the sprinkling water over it; this subjects it to decay in keeping. Brown malt, dried on one of these frames, will keep as well as any, if it be spread to cool as soon as made, and no tricks be played with it. All the damage it is subject to is, contracting something of a bitterness by burning ; but this is owing to the carelessness of the maker, more than the fault of the frame.

The carelessness of some, and the tricks of others, have turned these methods of the plate and tile frame out of fashion, but without any real cause. They are fit only for brown malts, but in a fair and proper management they dry these as well as any other of the methods, and much cheaper.

The wire frame comes next after the plate and tile ones, and now is generally used in their (lead. This dries the malt more gently and leisurely; but there is some difficulty in the turning it, and cleaning the bottom.

Of all the methods the plain and simple hair cloth is the best for the finest malts. A flow fire under this dries it very gradually and equally, it is easily turned as is required, and when it is done there is no difficulty in getting it out, for 'tis only turning it at once and all is clean.

Of the fuel to be used in drying malt.

The principal kinds of fuel are five: 1. Coak; 2. Welch- coal ; 3. Straw ; 4. Wood ; and 5. Dry fern or brakes. What is to be done by this fuel is to dry the malt, and nothing more : no flavour is required from it, and therefore the purer the fire is, and the cleaner the malt is dried by it the better. All smoak is wrong; and therefore all those fuels that yield a great deal of smoak, are to be rejected in the drying the nice malts.

Fern is a very bad fuel for this use : and at first fight a person might join wood and straw under the fame denomination, because of the quantity of smoak, but there is in this a difference. All smoak is an enemy to malt; but there are varieties in the taste and flavour of the smoak of different materials. The smoak of fern is not only plentiful, but of a very ill hogoe, which it will communicate to the malt. And the smoak of straw, though almost as plentiful as that of fern, is so sweet, that it scarce does any damage. The smoak of wood is of a middle nature.

Dividing our fuel into two general kinds ; the coak and welch coal being the best, and the straw, wood, and fern the inferior : the straw is the best of these, the wood the second, and the fern worst.

There never can be a necessity of using fern, therefore it ought wholly to be excluded : wood may always be had, and must be better than fern ; and for some of the ordinary malts it is a cheap fuel, and answers well. Straw, with good management, may he made to do for any but the very best and nicest kinds. With respect to the other two coak is the best; but the other is very good.

We advise the husbandman to use coak, if it is to be had ; but let him fee that it be good and well made: for otherwise the the inferior fuels may do better. Fine coak is made of large pit coal charr'd, or burnt to a cinder. It is to be burnt till all the ill smell is consumed, and no smoak rises; and in this condition it makes the steadiest and the sweetest fire of any fuel whatever. It is a common negligence to char this coal imperfectly, but the husbandman who dries his own malt should examine strictly into it; for one smoaky piece will do vast damage. He may fee this by the eye, for there is a particular dry aspect which coak has when well burnt, that is wanting in such as has any of its gross parts remaining.

The next to pure coak is welch coal: this is called by many culm. It is a fine sweet coal dug naturally out of the grounds It comes in thin fleaky pieces, and burns to white ashes with a little flame, and no smoak. This brings it nearer to the nature of coak, but it is not altogether so pure : however, it is cheaper in many places, and for all but the fine malts will very well answer.

Let the farmer, if he have convenience, dry his own malt, for out of this variety of materials it is possible the malster may chuse the worst: in some places it will not be worth while, because every thing must be built for it, and that the farmer may not think this proper, when he has a small family: but in other places most of the conveniences will be ready. In the hop countries the fame kiln that dries hops will dry malt ; and so on many other occasions; and wherever it can be done 'tis much best at home. As to a little expence, let him consider 'tis a thing for which there is a constant demand. I shall offend the malsters; but I must add, that if he knew their practices as well as I do, he would fee more reasons than are here set down for doing his business himself.

Source: "A Compleat Body Of Husbandry" by Thomas Hale, 1758, pages 316 - 319

If you're good I'll post the section on brewing from the book tomorrow.

18 comments:

Ron, which volume of the book are you using? The only malt information I can see is in Vol 4 but that is all about germination etc and nothing on drying.

Its a VERY large book, isn't it?

Mentaldental, it's volume III second edition.

http://books.google.com/books?pg=PA329&dq=fuel+to+dry+malt&lr=&as_drrb_is=b&as_minm_is=1&as_miny_is=1700&as_maxm_is=1&as_maxy_is=1900&id=sto6AAAAcAAJ&as_brr=0#v=onepage&q=fuel%20to%20dry%20malt&f=false

The treatise by Thomas Hale is interesting and not that dissimilar to Ellis's. The lack of timing information makes it difficult to draw conclusions. Perhaps it is best if I layout my take on malt.

The malts are:

1. Blown Malt

2. Brown Malt

3. Amber Malt

4. Pale Malt (sometimes called 'ordinary malt')

5 Pale Ale Malt (modern stuff).

2,3 and 4 are dried on the same type of kiln and do not differ much. 5 requires a radically different kiln design and kilning technique.

Blown Malt Requires a brisk fire at the instant of being thrown on the kiln, which pops the corn not dissimilar to torrefied cereals of today. The kiln floor was often made of perforated cast iron so that the corns popped the instant they hit it. It stays on the kiln for just four or five hours.

Brown malt Requires a brisk hardwood fire at the end of the kilning period. Smoke often encouraged by putting green hardwood on the fire just before turning it off the kiln. It is on the kiln for about twenty-four hours.

Amber Malt Accounts vary, but seems to have been little different, if at all, to Brown Malt, except, perhaps, for the enhanced smoking, but was still smoked by some accounts. Again on the kiln for twenty-four hours.

Pale Ordinary Malt Just a lighter version of amber, still dried over wood, still a brisk fire at the end of kilning, still on the kiln for twenty-four hours. A kiln floor made from the old-fashioned, traditional, house-hair matting was required for this. No iron, no wire or tiles.

Pale Ale malt Could not be produced on an industrial scale until, say, close to the turn of the nineteenth century. It required a different kiln to the traditional kiln. The kiln floor was raised to at least fifteen-feet above the furnace to keep the malt away from direct radiated heat from the furnace, such that only hot air passed through the grain. Accurate control of temperature required. It was on the kiln for FIVE DAYS (reduced to four in mid-Victorian times), with the temperature raised gradually each day. The fuel used was immaterial to a large extent, because the smoke can be ducted away, and was in some kiln designs. It also required much better barley than was grown in Hertfordshire at the time.

Contrast the timings with Ellis's London and Country Brewer, where he states "four, six or twelve hours", and implies that those are the timings appropriate for brown, amber and pale respectively. It'll be malt Jim, but not as we know it. He prattles on about straw as a fuel, but can you imagine keeping a controllable fire going for twenty-fours hours, leave alone five days, with just straw, on anything other than, perhaps, a farmhouse scale. For this, and similar reasons, I tend to treat much of what Ellis and his plagiarists say with considerable suspicion. He wasn't a brewer anyway, but a very bad farmer who took to writing about any subject he could earn money from. His brother was a brewer though.

It is this confusion between pale ordinary malt, and modern pale ale malt that causes so much bovver. However, it is not limited to modern historians getting it wrong. Contemporary accounts differ too, or at least writers seem to use terminology interchangeably. Black and Tizard are of similar times, but Black lumps blown malt and brown malt together as the same thing, which they clearly are not (drying methods are different), whereas Tizard treats them as two different malts and gives two different extracts for the two types. Black also treats amber malt as others treat brown malt.

Oh dear, I've exceeded my character-count allowance, as usual.

End of part one.

The Maltsters Guide, by Edward Skeate White, is interesting for a few reasons. Although his book was published in 1860, the methods are obviously from a much earlier period, which makes me think that much of it is plagiarised from an earlier work. However, it is the only reference that I have seen that makes a distinction between old-time pale malt (which he calls ordinary malt) and Pale Ale malt; plus he mentions that the kiln designs are different (Both statements I only noticed today). I looked at it today because I remembered that it gives temperatures, which is a rare treat, but timings are rarely mentioned.

On "ordinary malt" he seems to give the maximum temperature as 180F, but mentions the requirement of a brisk fire at the end of the kilning period from faggots. He moves directly on to amber malt. "Amber malt is finished in similar manner at a temperature of 185F which has the effect of imparting a higher colour" (again with a brisk fire at the end). He states that the smokiness is necessary for porter but he is still talking about what he calls amber malt when extolling the virtues of smoke. His fuel is coal or coke with hardwood laid on top.

He omits brown and moves straight to "porter malt" in which he is certainly describing blown malt. Blown malt must surely have been extinct long before 1860.

His treatment on pale [ale] malt is not extensive. After a brief discussion, including the quality of barley necessary, he dismisses it with the statement: "Pale malt, for the most part is only used by extensive brewers, and is regarded as being of a greater value than ordinary dried malt. Again, hardly likely to be true in 1860.

Graham, good stuff. I'll have to try and get hold of "The Maltsters Guide".

It's very hard to find good information about the characteristics of the different malts before 1900. I've seen PA malt often enough in brewing logs to realise it was a specific type of malt. But then again, there are quite a few other types of pale malt: mild malt, SA malt.

I can't remember out of my head the first year PA malt crops up. Older logs sometimes have white malt. If I remember rightly, PA and IPA were normally brewed from mostly PA malt, while for other ales it was pale malt.

Amber malt is all but impossible to pin down. Some books say that it varied greatly from maltster to maltster. And a maltster might use different methods for different customers.

Then of course, the barley varieties are all different.

I've a couple of 19th century books on malting. I really should read them.

All I can add is, my reading from the 1700's on suggests a range of malt colours from almost white to black and everything in between. The gradations are mentioned in Combrune with related kilning temperatures. White malt (I can show you a white Ware malt brewing recipes early 1800's) seems none other than slack malt, which was barley hardly germinated but just enough to form malt, a gristy malt.

It depended what the brewer wanted and what was available. The ales seem to have been white or yellow, in imitation of white wine probably. Certainly the gentry manor houses pale ales were. So was much pale ale and IPA. I quoted that source (not Hale, the other book I just mentioned) where he says the pale ale brewery supplied examples coloured from almost white to high amber - exactly what is in Combrune. This man was a brewer, quite evidently. It is all there.

Gary

Gary

I should add that I agree that ordinary malt would have been different from modern pale, not so much in colour, but from taste. Straw would impart a flavour and coke and coal do too (a kind of coal gas taste despite the smokeless nature of coke). Them beers had taste! But you can duplicate this today by subjecting pale malt to a light smoking process. Put it over smoulder straw for a bit and then make a not too hopped beer: circa-1800 ale is the result. You can do the same with various hardwoods. American brewers have been doing this for some time.

I have no hopes of ever making these malts myself, but I wonder if there would be enough world-wide (or even regional) demand for some maltster (or even a crazed start-up) to build a kiln that could reproduce these old malts.

maybe there are good reasons why the old malt styles were discontinued...

Ron,

I too would like to look at the complete book. I only have a printed transcript of the kilning section, along with transcripts of kilning sections from a couple of other works, sent to me by someone who was questioning my opinion on malt. Ironically, he should have read and digested the Edward White bit, because it more or less backs up my theories, although I must admit that I was not aware of that until today. There is also, a photocopy of the book's title page, and it apparently contains a "History of the Art of Malting from the earliest ages". That sounds interesting, but if it is like the kilning section it will not convey much information in addition to what is already known.

What is intriguing is that Edward White's description is so out-of-date for the time. I find it hard to believe that even his "ordinary malt" would have been in widespread use in 1860. However, it is easy to think that changes took place in those days as quickly as they do today. It probably took a lifetime for changes to propagate, and old methods could cling on for a half a century or more, and in some regions never die out.

Interestingly, the note accompanying the transcripts is dated Feb. 1997, so it seems that I have been fighting from my malt corner for at least twelve years.

Of course, my ideas as described are over-simplistic; there is a lot more to the story than space permitted. The blown malt / snapped malt description is not entirely accurate. Kilning time obviously did vary, even, I guess, as short as the twelve hours that Ellis recorded, although, at another guess, the malt could not have been very pale or very good.

Again, of course, pale malt close to what we understand it to be today would have always been around. Wind-dried malt, a typical farmer's method, whereby the malt was dried in the grain-drying loft of their barns, with the upper door open both ends, would pick up neither smoke nor colour. The weevils would have got it pretty damn quickly though, if it wasn't used straight away.

In bad weather or winter, farmers used to dry their malt in front of the kitchen fire on horse-hair mats stretched across hurdles. The chimney would take away the worst of the smoke. Hurdles being temporary fences typically used to hold sheep.

To this day, the drying floors of traditional malt kilns, if any still exist, are known as hurdles; a hangover from old-time farmer's methods.

An indirect oven, like a bread oven, could do small batches. Drying over charcoal would not generate much smoke. Charcoal was traditionally used for hops, no doubt it was used for malt also.

So, pale malt has always been around, in a small way at least.

Gary

In the past I have regarded white malt as being something akin to the wind-dried malt that I have alluded to in a previous post, or something like today's pale malt. It seems to also have applied lager malt, perhaps erroneously, in more recent times.

However, it appears that much white malt was bleached with sulphur. Edward Skeate White mentions this and calls for legislative interference to outlaw the practice. Not for the good of the malt or the public, I might add, but because the sulphur fumes were seriously damaging the health of the Excise officers who gauged every kiln-load, often several times, and sometimes entered 40 or 50 different kilns a day. But the poor blighter that had to turn the malt during the bleaching process was even more exposed, particularly if his employer had more than one kiln. But Mr White was not concerned about the malt shoveller, just the Excise man, which gives a strong clue as to what Edward Skeate White's true profession was. See! None of these authors are really what they seem to be.

Brown malt could not have been much darker than about 50EBC for logical and technical reasons.

In the first edition of my home brewing book, published in 1991, I gave a description of making and smoking brown malt in a large, tall, American-style barbecue-smoker that I bought at a local garden centre. I removed the description from later editions because it seems that American-style smokers were a one-off experiment that didn't last long, and people couldn't get them. They were also bloody expensive.

The first time I tried it I used some fancy wood-chips purchased from the same garden centre and the results were a disaster. Second time I used local beechwood, because that is what we have lots of around here, and the results were much better.

However, someone has shown me a couple of lonely hornbeam trees, minding their own business in the middle of a local field. I may creep out in the middle of the night and steal most of one of them.

Aaron,

French and Jupp, at Stanstead Abbots, still have two of their old brown-malt kilns, which they use as a show-piece. Doubt if they would dare to fire them up though.

I once tasted a premium blended whisky made in the 1930's. It had a faint aftertaste of coal or coal gas. The majority of the malts in there must have been kilned over coke. I know what (even denatured) coal smells like, my grandmother had a coal shed in the back of her triplex floor on Esplanade Street in Montreal. By the time I got to explore and play around there, it was disused, but there was the odd lump and plenty of coal dust to tell me what was in that wooden shed. Over 30 years later I tasted it in that whisky, and that taste would have been in beers whose malts were kilned in that fashion.

Gary

Gary:

Combrune's descriptions of malt colour are based on the results of experimentation which did not reproduce the actual conditions of kilning. If I remember correctly, he heated the green malt on an iron dish so there would have been no air-flow which is, of course, an important part of the kilning process. In fact Combrune has some pretty wild and wacky theories about a lot of stuff!

Graham:

In some respect change is still slow in 21st century. There are still ?5 floor malting operational in the UK and these are technically and financially anachronistic. But as they are all old and, I guess, paid for they continue and make a profit. I would imagine the financial cost of replacing them with more modern maltings would be prohibitive. Of course in the microbrewing world their malts are seen as a premium product which helps them keep going, I am sure.

As several later author's pointed out, Combrune's experiments with malt colour were a load of bollocks.

Gary,

The only coal suitable for malting in the early days was Pembroke coal, today what we would call anthracite - supposedly smokeless. It had to be shipped, by sea, from Swansea harbour. Any brewery not situated within a sensible carting distance of a navigable river, along suitable roads, could not get coal, leave alone the right sort, at a price and in the quantities necessary until we had a connected system of canals. Even for those close to a river, coal was exceedingly expensive compared to wood because of the coastal voyage and all the transshipment involved. So wood predominated in many areas. For example, a main artery, the Grand Junction Canal, started construction in 1794 but was not completed until 1815, so a place like Aylesbury, for example, could get not coal or coke economically until 1815, at which point coke became fairly economical, cheaper than Swansea coal although more expensive to produce, because the coke could be transported over land from the coal fields of the midlands, where the coal itself was unsuitable. After the railways coal became cheaper than coke, until the situation reversed again when the widespread production of coal gas produced surplus coke as a by-product, until demand exceeded supply and the situation reversed again.

Indeed, our pale ale revolution could not have occurred when it did, without the canals. Local barley was usually unsuitable and had to be shipped in from elsewhere, coal or coke had to be shipped in. It is no wonder that many of our famous pale ale breweries were founded during this period and situated alongside canals.

Anyway, I digress (if only Patto had a discussion forum). So technically, the coal used was smokeless, but in the preface to Christine Clarke's book, The British malting industry since 1830 which I have been looking at on Google Books, George Paul of Pauls Malt says that when he went to work at Daddy's Maltings in 1962, he was immediately packed off to work elsewhere, at Stoneham maltings, basically shovelling malt. He says: "[When] we were working on the wire floor of the kilns, the fumes from the damped down coal fires rasped the backs of our throats". So, the coal was not without its fumes, it seems.

Malt-kiln fires were never extinguished, except for maintenance, even during shutdown periods and holidays, just damped down and starved of air. A wire-framed floor seems pretty old-fashioned for 1962 - I wonder what they were making there. The maltings must have been pretty ancient, and there must have been a good reason for keeping the frames and not replacing them with maintenance-free earthenware tiles.

Graham, "The British malting industry since 1830" There's another book I own but haven't had time to read yet.

Your point about transport is a very good one. Heavy stuff like coal (or beer) wasn't easy to shift around before the canals. Burton only became a major brewing centre after the canal and rail networks were built.

I thought this was my discussion forum.

Ron,

Well yes, this is your forum, but that might not have been your original intention.

The River Trent and the Trent and Mersey Canal was the real secret of Burton's success. The port of Hull up the river, the port of Liverpool up the canal, London down the canal, and transport to any major industrial centre of the country. Yea, of course it was all to do with their water, but not the water they actually brewed from.

Gary:

Islay whisky is made from peat-smoked malt.

If you go into any supermarket you will find smoked ham, smoked bacon, smoked beef, smoked sausage, smoked cheese, smoked fish, smoked whisky, even some of the fancy tea is nothing other than smoked tea-leaves. Go into a delicatessen and you will find lots more smoked foods.

Americans maintain smoking traditions much more than we do and have a large range of smoked foods more readily available. A British barbecue is nothing other than a charcoal-powered grill. American barbecues are smokers, not grills, that will even cold-smoke; cooking the food isn't the primary function of an American barbecue - smoking is.

Smoking, like sulphuring and salting, was a curing or food preservation process, and was just about all that was available in the old days. As far as grain was concerned it kept the weevils and mildew at bay during storage. Malt is particularly susceptible because once the barley has been processed and cooked in the kiln, its natural defences have been destroyed.

The Australians have demonstrated that hanging burnt corks off your hat keeps the flies away. The same thing applies to smoked food - maggot-free ham and pest-free malt.

I therefore find it bemusing that so many people find it difficult to accept that old-time beers were smoky.

Incidentally, the invention of bacon (technically pork preserved with saltpetre) is attributed to Roger Bacon, who performed many experiments in food preservation.

The same Roger Bacon is also attributed with the invention of gunpowder, at least in the west. Gunpowder is made from charcoal, sulphur and saltpetre (potassium nitrate), all of which are materials that were traditionally used in the preservation of food. Curious isn't it?

Now, my theory is that Roger Bacon accidentally discovered gunpowder by blowing himself up while trying to cure a pork chop. What do you think?

Graham and Ron: Thanks for this further discussion, with which I am just catching up. I am on the road (to the Kentucky Bourbon Festival - speaking of charring - barrels in this case!) but beer history is never far from my mind.

I know about the later doubts expressed about Combrune's temperatures, he got them wrong supposedly. But my point was the range of malt colours he identified, clearly they all existed in his time. He was simply trying to explain at what temperature you could kiln them.

Gary

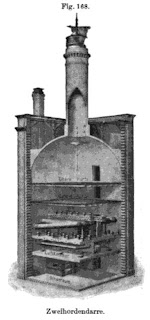

The illustration accompanying this topic illustrates one of the points I made elsewhere; namely that the type of fuel used was immaterial in some kiln designs.

Although indistinct, the illustration clearly shows metal pipe-work used to duct the smoke away. It is ducting the smoke from the internal furnace. The chimney that takes the smoke away can be seen at the back of the building. The pipe-work will serve to scavenge some of the heat that would otherwise disappear up the chimney, and distribute it.

Obviously, the fuel could be anything from uranium to camel-dung.

Other observations are the two drying floors at the top, the top one being cooler where the fresh malt would be loaded. After a day or so it would be dropped to the hotter floor below.

The floor below the major pipe work has lots of little chimneys, air ducts, passing through the floor that evenly distribute the hot air over the whole area of the kiln's upper floors. Controllable external air, from adjustable external vents, would come in below this floor to be heated in the heating chamber.

From the illustration it seems that there may be malt on this floor. If that is the case, this floor is also used for finishing the malt; colouring it by direct radiated heat from the furnace (rather than heated air passing through the malt, as on the upper floors).

The very bottom floor, just above the furnace, seems to be a heat spreader. It appears to have an array of adjustable vents in it, again to evenly distribute the hot air over the whole area in a controllable fashion. In which case the external air-intake vents would be below this floor, set into the wall at ground level.

Although German, this seems to be an intermediate stage between the traditional brown malt kiln and the British Victorian four-floor tower kilns. It is capable of producing smoke-free pale malt close to the modern sort.

The maltster who specialised in common malt or brown malt, as all of them were at one time, only kept his malt on the kiln for twelve to twenty-four hours. He got a kiln-load of malt out of his malt house every day. However, pale ale malt requires four or five days on the kiln, so if a maltster moved from brown or common pale malt to pale ale malt, his malting capacity dropped to between 20% and 25% of his previous capacity. He certainly would want compensation for this, and pale ale malt was much more expensive than common malt for this reason. If he was rich enough he could build more kilns, of course, but each kiln would require its four-days-worth loading of fuel, and the kiln itself was capital equipment tied up for four days, so it still did not lower the price of pale ale malt. And that assumes that he could control temperature and airflow sufficiently well to make pale malt, which usually was not the case because the drying floor was almost on top of the furnace in old-time kilns.

Tower kilns had four floors, one above the other. The green malt was loaded onto the top (coolest) floor. Every day a batch of finished malt was taken off the bottom floor and then the malt on each of the upper floors was dropped to the hotter floor immediately below, a new batch of green malt being loaded onto the top floor each day. The maltster got a batch of malt out of his kiln every day, and a quarter of the fuel was required when compared to four separate kilns.

Post a Comment