We're moving on from the mashing stage to the coppers. I'll have something to say about the equpment there later.

"We next bent our steps to the copper stage, situated in a portion of the boiler-house, where there are two large coppers, heated by steam, and from whence we had a fine view of the engines and great steam boilers. Following the process, we next proceeded to the cooling house, situated on the left side of the brewhouse, and adjoining the hop stores. It is 104 feet in length, and contains four open coolers, commanding one another, all resting on iron columns and joists of massive construction ; also two vertical refrigerators, of the most modern pattern, cooling at the rate of sixty barrels per hour. This is a very cool place, even in the summer time, as the walls are louvred on all sides, and a box louvre fixed along the centre of the roof.

"Noted Breweries of Great Britain and Ireland, vol III", by Alfred Barnard, 1890, pages 136-137.

The cooler is a stupidly simple piece of equipment. Yet it's use has come to be almost totally misunderstood. A cooler is a large, extremely shallow, square vessel. It was located high up in the building in a room with louvred windows to allow the floww of air over the wort. Its primary function was to cool wort, but it also helped clear the wort of debris. Being very shallow, anything suspended in the wort would quickly fall to the bottom, forming "cooler sludge".

If I tell you the German name of this piece of equipment, you'll probably guess what the modern misunderstanding of it is. The German word is Kühlschiff, often incorrectly translated into English as coolship. The real English word is cooler. For some reason, people havbe got it into their heads that coolers are connected with the brewing of sponrtaneously fermented beer. Some even that think they are fermentation vessels. They aren't. They're just a way of cooling wort.

Let's make this very clear: every brewery in Britain had a cooler. They didn't start disappearing until well into the 20th century. Even after the development of paraflow coolers like the Morten's refrigerator and artificial refrigeration, breweries continued to use coolers. Nothing to do with spontaneous fermentation.

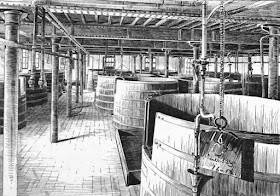

Eldridge Pope's fermenting room in the 1890's.

"After cooling, next follows fermentation, which is conducted in a separate building.

There are several methods or systems of attenuation, such as the London, Burton, Yorkshire and Edinburgh systems, all of which lead to one result. At the Dorchester Brewery, that known as the skimming system, as practised in London and elsewhere, is the one adopted, or rather that has been in use since the brewery was founded.

We were charmed with the lightness and cleanliness of the tun room, its white walls and ventilating windows. This lofty room, measuring some 80 feet square, contains sixteen fermenting rounds, with a total capacity of nearly 2,000 barrels. Three of them, recently manufactured and erected by Wilson, of Frome, which hold about 160 barrels each, are of English oak, and well worthy of admiration. On the floor, between each pair of vessels, are ten shallow but capacious yeast-backs, constructed of slate, for receiving the yeast from the "fermenting rounds" which is skimmed from the top of the beer to an outlet on the side of each vessel. All the "rounds" have attemperators, either fixed or movable, for cooling the beer during the process of fermentation. Here, on this level, overlooking the tun room, is the brewer's office and laboratory, most pleasantly situated, with a bay window having a full command of the yard. Both are most completely fitted up and furnished; and the latter contains many scientific instruments, including Mr. Crouch's useful brewers' microscope. Here we found the head brewer, and his able assistant, busy testing yeast for the day's pitching. The former stated that a change of yeast has not occurred for two years, as the present sample retains its working

purity."

"Noted Breweries of Great Britain and Ireland, vol III", by Alfred Barnard, 1890, Page 137-138.

The skimming system was one of the methods of cleansing, rather than fermentation per se. Like Burton unions, the dropping system or pontos, it was basically a method of removing yeast from the wort. Whereas the latter three all required extra vessels, skimming was performed in the fermenter. Yeast was removed from the the wort by skimming it from the top, often using a parachute - a cone which floated on the top of the surface. Yeast was pushed into it by a plank moved across the surface of the wort. In this case, it sounds like there was no parachute but something attached to the side of the fermenter. The skimmings were moved to slate yeast backs, where presumably any wort skimmed off with the yeast was recovered.

The yeast backs were arranged between the fermenting vessels in an arrangement like this:

the circles are the round fermenters, the rectangles the yeast backs.

I believe that you can also see the end of a yeast back behind the fermenter in the foreground in the illustration taken from Barnard. The hatch on the left of the fermenter is presumably connected with skimming off the yeast.

The presence of a laboratory and the use of a mircoscope to check the yeast is a sign that the Dorchester Brewery was modern and well-equipped. Microscopes first came into use in breweries in the 1870's. Whitbread bought theirs immediately after Pasteur had visited the brewery in 1871 and used a microscope to highlight problems with their yeast.

Just the vat-house to go then we'll be onto descriptions of Eldridge Pope's beers themselves.

The German "Kühlschiff(e)" becoming "coolship" (sometimes "cool ship") in English seems to have become common by the late 19th century in the US (where else?). Not sure if was the German-born brewers or just English speakers who first adopted it, however.

ReplyDeleteEarliest usage I've found was in an article about a Trenton, NJ brewery - see a excerpt here (hopefully the link'll work):

https://sites.google.com/site/jesskidden/jk%27smisc.beerpages/coors-coolship/TrentonCoolship2.jpg?attredirects=0

In Ehret's 25 Years of Brewing (1891) he used the term "cooling tank" and had a nice illustration of his on page 53. Other 19th century US books refer to them as "surface coolers".

After Repeal, the US industry seems to more commonly call them "coolships" - it's used (along with a photo) in 1947's The Practical Brewer, on a Ballantine schematic of their brewing process, and in ads from Coors after they installed what they claimed was the only "solid copper coolship in the world" in 1930's.

Jess,

ReplyDeletethanks for that. It doesn't surprise me that it's been adopted from German. I've seen the level of German influence at Amsdell by 1900.

The term in English is earlier than 1892, it is used in this 1870 U.S. patent claim by Oscar Lewis, out of Cincinnati. Zinzinnati was famously a German-influenced town and so it makes sense it came in via German-American brewers. I'd infer it was a working term of art in American breweries from at least this time, and only much later did formal usage (in texts and ad copy and such) acquire legs. I have never seen the term in a British text but didn't search very hard to confirm.

ReplyDeletehttp://books.google.ca/books?id=6F1TAAAAcAAJ&pg=PA835&dq=coolship+%2B+beer&hl=en&sa=X&ei=kbsaUdSfLaeqyAGdhIGQAw&ved=0CDwQ6AEwAg#v=onepage&q=coolship%20%2B%20beer&f=false

Gary

Gary, I've never seen coolship used in British English, at least not in texts more than 30 years old. Some geeky modern writers have probably picked up the word.

ReplyDelete