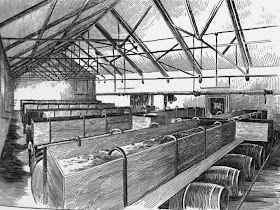

"HAVING refreshed ourselves, we proceeded to the fermenting department, and first entered a lofty place called the fermenting rounds room, similarly constructed to the cooling chamber, with iron principals, etc.; the walls being lined with white glazed bricks. This room, which is over the hop loft, possesses a concreted sub-floor, like the one under the mashing stage, only that it is two feet higher. Here are to be seen the fermenting rounds, constructed of pine wood, and connected with the refrigerators by a copper main, running down the centre of the room.

Walking through this apartment, we came to a much larger one, of very handsome appearance, called the union room, of the same construction as the fermenting-round room, just described. In designing the fermenting department, in this brewery, the object seems to have been, that, wherever fermentation is to be carried on, there should be no floors above, so as to insure light and free ventilation.

This lofty chamber, which measures 134 feet in length, by a width of 60 feet, is the most magnificent of the suite. The asphalte floor is entirely covered with iron frames for holding 216 union casks, and over them are the usual yeast troughs, containing fixed attemperators. Along the centre of the roof there is an elevated framed window, louvred, and placed above the iron principals, which is controlled from the floor by a lever which acts in a very simple and ingenious manner. Before leaving this department. we walked through the union room in the old brewhouse, which is still utilized for its original purpose, and contains seventy union casks, on wooden frames.

Descending a long flight of steps, we reached the room first entered, where the racking operations are carried on. The floor is paved with blue bricks, set on end, which rest on concrete arches, rendering it like all the others - water-tight and fire-proof. At one end, and extending under a portion of the old brewery, there is another racking room, of much smaller dimensions, that did duty in the olden times. In the centre of the racking hall, next visited are several lofty racking vessels, each holding 120 barrels, attached to which are the usual stop-cocks and hose, for filling the beer into the casks. The ceiling of this room, which is necessarily of great solidity, is supported by twenty-seven massive iron columns, and the place is lighted by numerous windows opening into the yard. At the western end, there is a powerful steam lift, for lowering or raising the filled casks, to or from the spacious cellars below, which is worked by a small engine, placed in the basement This engine also works the steam hoist, for lifting the hops to the hop loft.

Following our unwearied guide, we descended to the basement ot this, and the adjoining building, to inspect the stores. These lofty and extensive cellars, which, like the floor above, are paved with blue brick, contained at the time of our visit, about 2,500 casks of ale. Besides these cellars, there are the other great stores, situated beneath the maltings, before described. Great attention has been paid to the ventilation of both places; but these, unlike the others, are lighted throughout with gas, and contain a storekeeper's office and tasting room. Retracing our steps to the racking room, we passed out of one of the noble doorways leading on to the ale-loading bank, always a very busy place. Here numbers of men were seen rolling the barrels of beer into the trucks, the floors of which are on a level with the platform.

There is a double line of railway, in this part of the yard, fronting the racking room, and therefore as many as twenty trucks can be loaded-up with ale at one time."

"Noted Breweries of Great Britain and Ireland, vol. 2", Alfred Barnard, 1889, page 232 - 235.

Iron principals. I suspect Barnard doesn't mean firmly held beliefs, but pillars. The brewery sounds quite flash, with all its glazed tiles and open, airy spaces. In the late 19th century especially, breweries were often more than purely functional. The owners wanted them to look nice, too. Breweries, especially large modern ones, had been attracting visitors since the 18th century, when many came to marvel at the majesty of Barclay Perkins, Truman or Whitbread. That could explain the apparent extravagance of some designs.

For once Barnard doesn't come up with much details on the size of the fermemnters. As we've already learned, the fermenting vessels were often unusually small in Burton, in comparison to the quantity of beer being brewed. The picture doesn't help much, as there are no figures to help scale it. They look a fair size. Definitely bigger than the 15 barrels that Allsopp's fermenter contained. Or the 40 barrel fermenters at Salt or even the 45 barrels ones at Bass. I reckon we can only see the top half of these babies. That's a stage rather than the floor.

The fermenters were wooden, made from pine. Does anyone still use wooden fermenters? I can't they're very easy to keep sterile. Or maybe that wasn't the idea. Gale's were the last brewery I know to have used unlined wooden fermenters. And they seem to have been a real headache, unless you were brewing Old Ale. In which case they were perfect.

The copper main must be the large pipe running down the centre of the room between the fermenters.

On to the unions. The union room is much more modest than those we've seen at Salt, Bass and Allsopp. The arrangement of the troughs, casks and swan necks, however, is pretty much the same. Nice little detail about the attemperators in the yeast troughs. Was that standard? Hard to tell, as Barnard made no mention of themn at other breweries. It would make sense to have them. You wouldn't want the beer in the troughs getting too warm.

2,500 barrels is a fair stock of beer. Remember that Burton Pale Ale was a Stock Beer, that required several months of storage and maturation before sale. Eadie's output was around 70,000 barrels a year, so that's a little less than two week's production. Seems quite modest, really. I'd have expected more like a couple of month's work. But it could just be that most was held by agents or in bottling stores elsewhere.

I've left in the detail description of the loading bay to emphasise how vital the railways were for the development of Burton's brewing industry. The town was criss-crossed with private railways that brought in raw materials and connected breweries to their maltings. And, of course, fed trucks laden with barrels of beer into the railway network and into every corner of the kingdom.

And that's it for Eadie. I've still a few Burton brewers to go. Including one that's still brewing.

A lot of whisky distilleries have wooded fermenters (wash backs), as they don't need to be as sterile as they would in a brewery.

ReplyDeleteThe Traquair House brewery still seem to use unlined wooden wessels.

ReplyDeletehttp://www.traquair.co.uk/content/how-beer-is-brewed